28 Sep CRANE UPGRADE TO 320 TONS

UPGRADE PRODUCTIONHALL CRANE TO 320 TONS

An overhead crane with a lifting capacity of 250 tons has been upgraded to 320 tons by MIT.

The existing overhead crane in a production hall was equipped with two trolleys, each with a capacity of 125 tons and at our client request its capacity was temporarily upgraded to 160 tonnes per trolley.

The runway construction and crane girders had proved to be suitable for this heavier load and here was no need for adjustment. Both crane trolleys have been adapted by MIT so that the hoisting ropes again be reeved once more. At each trolley 2 cable sheaves were added. As a result, the burden on the hoisting winch remains unchanged.

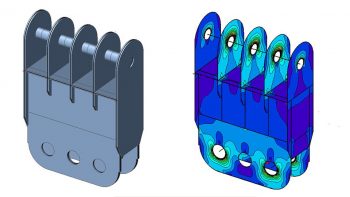

And for each trolley a custom fit lifting block was made with sufficient weight of itsself that is constructed to fit the necessary slings and grommets. The newly produced lower blocks have been developed by MIT itself. The intended design was calculated entirely for the use with a 160 tons load. On the basis of these calculations the final embodiment of the lower blocks has been determined.

With this final design the production started and the lower block constructions were assembled. Because of the required very short lead time of only a few weeks the required cable sheaves were also produced in-house. After the lifting blocks, with shafts and cable sheaves were assembled we tested them on a tensile testing machine, after which they are placed in the crane trolleys.

The crane is tested and the safety switches were readjusted based on the increased lifting capacity.